NEVEON offers a variety of processing techniques, including cutting, forming, and laminating. This allows us to precisely adapt our high-quality foams to the specific requirements of different end applications, producing semi-finished and finished products for various industries and retailers.

Our processing techniques

Loopsplitting

Process: Splitting of 60-meter-long foam blocks into rolls with cut thicknesses from 1.7 mm to 100 mm.

Application examples: Textile industry, automotive industry, construction industry, mechanical engineering.

Horizontal and vertical cutting

Process: Vertical and horizontal cutting of short blocks into sheets for further processing in-house or by customers.

Application examples: Comfort applications, acoustic sector, automotive sector, and aviation.

Contour cutting

Process: CNC cutting to produce any shape in 2D.

Application examples: Comfort applications, technical applications.

Water jet cutting

Process: Creation of precise foam cuts (PUR, PE, PP foams, and EPS foams) using a high-pressure water jet.

Application examples: Customized packaging, contour cuts for technical applications, and the comfort sector.

Shape cutting (compression cutting)

Process: PU is pressed into a mold and cut flush, creating a precise 3D indentation when the pressure is released.

Application examples: Packaging for highly sensitive products, medical accessories.

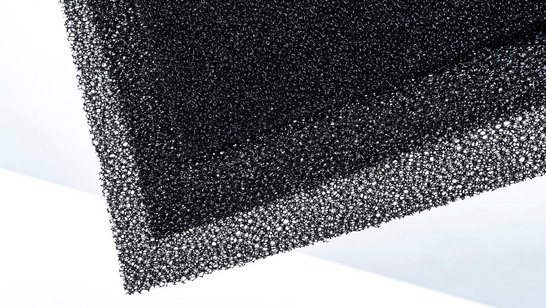

Thermal reticulation

Process: Removal of the cell walls to completely open the foam structure.

Application examples: PU as a carrier medium for activated carbon and other substances, acoustics, outdoor furniture, air, water, and dust filters, applications in the automotive industry.

Milling

Process: Mechanical process in which the foam is removed in order to create 3D shapes or complex patterns.

Application examples: Toolbox inserts, packaging sector, medical accessories.

Die cutting

Process: Foams are cut into the desired shape using customized tools.

Application examples: Industry, packaging, comfort sector.

SMT (surface modification technology)

Process: Surface treatment of foam sheets or foam strips using a profiled roller.

Application examples: Mattresses, toppers.

Profiling (castellated sheets)

Process: Waste-free creation of surface profiles by cutting foam sheets or strips in the middle between two profiled rollers.

Application examples: Mattresses, toppers, packaging, acoustics.